Glenmark Pharmaceutical Plant

A 9m high, 52° reinforced soil slope was built at Glenmark Pharmaceutical Ltd manufacturing facility at Samlik Marchak village in the state of Sikkim, India, to replace a failed masonry retaining wall.

Benefits

- 40% cost savings over conventional retaining structures

- 2 months construction time

- Reduced carbon footprint and no use of concrete

- Flexible soil structure with simple construction and longevity of strucutre

Glenmark’s manufacturing facility is located in the Sikkim state, North-East India and the hills in this area are part of the Himalayas. Therefore, this region is prone to high seismic activities. The masonry wall that was built around the manufacturing facility towards the valley side developed cracks due to erosion of the toe slope. As a result, the manufacturing facility building was exposed to risk of settlement and possibly instability. The client needed to replace the failed wall and provide erosion control measures, but with minimal dust and business disruption.

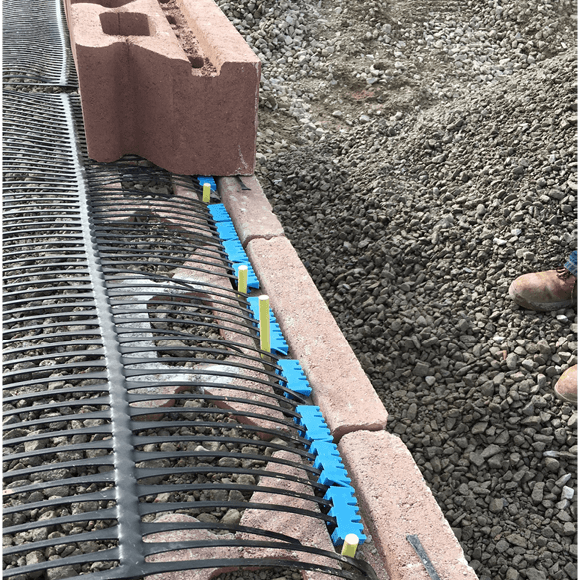

After careful review of site conditions and constraints, Tensar suggested a scheme using a steep reinforced soil slope with wrap-around facing along with the need for drainage and erosion control measures at the toe of the slope. This suggested solution allowed the use of locally available soil for construction of the slope structure which reduced the cost of construction. This cost effective, flexible, and eco-friendly scheme was adopted by the consultant and approved by the client.