The term ‘floating road’ has today become synonymous with a relatively thin road embankment incorporating a stabilisation geogrid, often constructed directly on peat. By keeping the overall structure of floating roads as thin as practically possible, surcharge weight is minimised, reducing geotechnical settlements, and limiting environmental and hydrological impact.

Construction of roads and platforms over peat has always been a challenge. Expansion of onshore wind farm construction to address the climate change challenge, has renewed interest in finding economic and sustainable solutions to this problem. Floating roads have become the preferred solution.

Within this article, we’ll look at:

- What is a floating road in construction?

- Where are floating roads used?

- The challenge of construction on peat

- What is peat?

- Environmental concerns when constructing on peat

- History and development of floating roads

- The use of lightweight fill in floating road construction

- Floating roads vs excavation and displacement of peat

- When should floating roads be used?

- Design of floating roads on peat

- Construction of floating roads on peat

What is a floating road in construction?

A floating road on peat relies on the strength of the in-situ peat to support the road structure. The road is not actually floating, but it relies on an equilibrium existing between the weight of the road structure and the support from the peat. To achieve this, the road needs to weigh as little as practicably possible and have sufficient stiffness to resist road rutting and to distribute load over the peat.

Modern floating roads are typically constructed with a layer of geogrid at the base. This acts as a separator between aggregate fill and the peat and combines with the aggregate above to form a mechanically stabilised layer. This stabilised layer provides the required strength and stiffness to enable overall road thickness and weight to be minimised.

.png)

Figure 1- Tensar stabilised floating road construction minimises disruption to environmentally sensitive peat bog (Source SSE Renewables)

Where are floating roads used?

Floating roads have been found to be of great value when there is a need to cross a peatland. While most floating roads are unsurfaced, the technique has been successfully adopted for low volume surfaced roads. The same ‘floating’ technique has also been successfully used for rail embankments over peat.

Floating roads are not the solution for every site. Suitability of the method will depend upon several site-specific factors, including:

- The type, geomorphology, and characteristics of the peat

- Depth of the peat

- Underlying geology

- Gradient of the peat and underlying stratum

- Hydrology of the site

- Function of the road

- Rate of construction

- Traffic loading, during construction and in service

Floating roads vs elevated roads

Unlike floating roads which are constructed directly on unstable surfaces such as peat, elevated roads are constructed above ground level, supported by solid fill or columns.

-(1).jpg)

The challenge of construction on peat

Peat typically comprises mostly water – typically, between 80 to 95% water content. Some structural integrity is provided by the fibrous nature of the organic material This fibrous structure is highly permeable and highly compressible. Settlement under load is therefore inevitable. Couple this with low shear strength, and the challenge of constructing anything on peat is clear to all.

What is peat?

Peat is formed over time from the remains of plant matter where the land is permanently very wet. The lack of oxygen prevents natural decomposition of the dead plant material. An organic soil is formed, containing more than 60% of organic matter. Areas of peat comprise a thin surface layer of living vegetation (the acrotelm), overlying a thicker layer of consolidated and well decayed former surface vegetation (the catotelm). Below that is the substrate of soil or bedrock.

.png) Figure 2 - The structure of peat

Figure 2 - The structure of peat

Strength of peat

The engineering characteristics of peat are dominated by the high water content. The higher the water content, the lower the shear strength. The fibre content also has some effect. The more fibrous and woodier the peat, the higher the shear strength. The higher the degree of decay, the lower the shear strength. Unlike most soils, strength does not usually increase with depth. The amorphous, non-fibrous peat at depth will typically have a lower shear strength than the upper layers of fibrous peat.

When peat is loaded it can behave in two ways:

- Slow response – water is forced out of the peat mass resulting in a volume change and slow steady settlement.

- Rapid response – sudden shearing of the peat mass leading to failure.

The actual behaviour will depend upon the geomorphology and depth of the peat, the water content, and importantly, the rate of loading.

Compression and settlement of peat

Peat normally exhibits two phases of settlement under load:

- Initial settlement phase – In this phase, the primary consolidation phase, the applied loading is jointly supported by the free water within the peat and the fibrous peat layers. Water is forced out into the unloaded adjacent peat, transferring load onto the fibrous material. This phase usually occurs during placement of the fill layers and settlements are large – up to 50% of the final settlement. The magnitude of settlement will depend upon the weight of the road layers and thickness of the peat deposit. Once the excess pore water pressure is dissipated, secondary settlement begins.

- Secondary settlement phase – Loading continues to transfer from water pressure to the peat structure as fibrous materials slip, re-organise, and densify under sustained loading. A process that can take several decades.

It is obvious that peat should be loaded slowly and uniformly to allow the underlying structure to accept the increased load without shear. Settlement will always occur, but minimising surcharge loading will reduce both primary and secondary settlement.

Environmental concerns when constructing on peat.

- Carbon store – Peat can be considered as a carbon sink supported on a long-term carbon store. In the UK, peatland stores 3.2 billion tonnes of carbon, with peat samples having been shown to contain up to 55% carbon by mass. Globally, while peatlands comprise just 3% of land area, they hold 30% of all soil carbon. Excavation or drainage of peat can release that carbon to the atmosphere and should be avoided.

- Unique habitats – Blanket peat bogs are a globally rare habitat supporting many different plants, insects, and birds. In the UK and Europe, much of it is covered by protective legislation.

- Hydrology – The hydrology of peat areas supports the local ecology and habitat. A typical peat layer has two hydrological zones. The upper fibrous layer – the acrotelm, can experience ‘rapid’ water flow responding to stormwater changes. While the permanently waterlogged amorphous, catotelm layer will have slow permeation in the direction of a sloping substrate. Any change in hydrology will influence the local ecology and should be avoided. Displacement of peat, removal and backfilling with rock, or unduly thick floating roads can have a highly detrimental effect on the hydrology of a site by acting as a barrier to lateral water flows or by providing new drainage paths. An access road traversing a sloping site can result in ponding on the upstream slope and desiccation of the adjacent downslope area, greatly affecting the ecology and habitat.

History and development of floating roads

Peat is usually considered to be unsuitable as a road foundation, but tracks over peatland have been necessary since the beginning of human existence. In more recent times, construction over peat, when necessary, has often been seen as a ‘black art’, based on acquired knowledge (and trial and error), rather than a defined engineering practice. This usually leads engineers to adopt a highly conservative approach.

Early trackways over peat will have been created by the passage of animals and humans compressing and densifying the peat layer. By the arrival of the wheel in the bronze-age, tracks over peat would have been improved using bundles of twigs or logs as a foundation – a technique called corduroy. When placed in saturated peat, the timber decays only very slowly. The logs are laid across the track width, supporting a layer of fill above, and distributing load across the width of the track. These were the first ‘floating’ roads.

The corduroy technique has been in continuous use and is still followed today in many parts of the world. While most suited to unsurfaced roads, corduroy has been used for construction of surfaced roads. The first major highway in Canada over peat, the Louheed Highway near Maillaedville was built in 1954 using the corduroy technique.

One of the most impressive uses of ‘floating’ construction must be the crossing of Chat Moss, to build the first commercial railway for steam locomotives in the world.

Floating a railway on Chat Moss peat bog

The Liverpool to Manchester railway opened in September 1830 was the worlds first commercial railway dedicated to the new steam engines. The rail track, constructed by George Stephenson faced some major challenges, the greatest of these was the crossing of Chat Moss. This peat bog, ranging from 4 m to 9 m in depth, had been described by Samuel Smiles, a contemporary writer, as, “an immense bog of about twelve square miles, a mass of spongy vegetable pulp”.

Stephenson chose to build a low embankment on a mattress of brushwood bundles and timber hurdles (or timber grids), each 2.5m by 1.2m. The brushwood and hurdles were assembled to form a raft directly on the peat surface. Over this was constructed the embankment and track. The first train to use the new track was the famous Stephenson’s ‘Rocket’. The original floating embankment is still in use today carrying locomotives that are over 25 times the weight of the ‘Rocket’. This is possibly the first documented use of a geomattress type solution for construction over peat.

.png) Figure 3 - The crossing of Chat Moss by the Liverpool and Manchester Railway 1831/1833. Artist Henry Pyall.

Figure 3 - The crossing of Chat Moss by the Liverpool and Manchester Railway 1831/1833. Artist Henry Pyall.

Modern floating road construction using geogrids

Geogrids were invented in the late 1970 s and quickly proved their value for construction over weak soils. Interestingly, the first geogrids were developed and manufactured in Blackburn, just 30 miles from Chat Moss, the site of the first use of a geomattress foundation over peat. The first documented use of a geogrid for construction over peat occurred in August 1982. Tensar geogrid was successfully used to construct a 9,000 m2 drilling pad and access roads for oil exploration at Sturgeon Lake, Alberta, Canada. Since then, geogrids have become the standard solution for the construction of floating roads over peat. Millions of square metres of Tensar geogrid have been used for construction of floating roads and platforms over peat across the globe.

The use of lightweight fill in floating road construction

The need to minimise surcharge loads to limit settlement of the peat is clear. The use of efficient stabilisation geogrids offers an opportunity to design thinner road structures. An additional method to reducing surcharge load, used in combination with geogrid stabilisation, is the use of lightweight fill.

An early example of this would be the Burnaby Freeway section of the Trans-Canada Highway. Sawdust was used in 1958 as a lightweight fill for the first time in Canada. The deep peat was underlain by a very soft clay, and this was to be dewatered by insertion of vertical sand drains. The sawdust thickness varied from 1m to 4m, providing volume while minimising weight. This was then capped with a layer of aggregate. This floating structure provided a stable platform for installation of the sand drains and surcharge to improve the underlying clay. It remained in place as part of the permanent road embankment. The project was monitored, and the results published. The authors concluded that the final sawdust level needed to be below the permanent water table to prevent rotting or spontaneous combustion!

.jpg) Figure 4 - Floating road construction using sawdust lightweight fill (Lea & Brewer 1962)

Figure 4 - Floating road construction using sawdust lightweight fill (Lea & Brewer 1962)

A much more recent example of lightweight fill being used for a permanent floating road comes from Scotland. As part of the Viking Windfarm project, a section of Sandwell Road, a public ‘B’ class road with asphalt surfacing, was realigned. The new construction, completed in 2023, included several sections over peat. A manufactured lightweight aggregate, less than 20% of the weight of conventional aggregate, was used in combination with Tensar stabilisation geogrid to minimise settlements.

.png) Figure 5 - Realignment of public road sections over peat using Leca® lightweight fill and Tensar stabilisation geogrid (source SSE Renewables)

Figure 5 - Realignment of public road sections over peat using Leca® lightweight fill and Tensar stabilisation geogrid (source SSE Renewables)

Floating roads vs excavation and displacement of peat

In the past, the preferred means of construction on peatland has involved either displacement or excavation of the peat. With displacement, fill is tipped over the peat, forcing the peat to collapse and displace laterally. Filling continues until an embankment is formed, transferring load directly onto the substrate. The alternative is to excavate the full depth of peat and backfill with imported material, usually quarried rock.

This may minimise risk but comes with a high economic and environmental cost. The volume of imported quarried stone has a high carbon cost - from the quarrying and crushing of rock, plus transportation to the site. The material cost is also high combined with indirect costs from disruption and damage to local roads leading to the site.

The buried embankments formed by displacement and excavation methods create a massive disruption to the local hydrology. This can result in ponding of water on the upside slopes and drying out of the peat on the downside slopes. Excavation and backfill can also create new drainage paths leading to drying out of adjacent peat. Each of these hydrological disruptions impact adversely on the ecology and habitat over potentially large areas.

Floating roads, by their nature, minimise the depth of peat affected and any impact on the hydrology of the site. They use significantly less imported fill material, minimising economic and carbon costs, and limiting the impact on local roads.

When should a floating road be used?

Floating roads are appropriate for peat deposits of any depth, however for peat depths of 1.0 m or less, excavation and replacement may be an economic alternative. This will depend upon the possibility of re-using the excavated peat local to the site.

Not every site is suited to floating road construction. A full and detailed ground survey by a qualified engineering geologist with specialist knowledge of peat is essential to characterise the peat and the local hydrology, and to advise on peat stability.

The decision on when to use a floating road solution will depend upon site specific circumstances.

- The type and geomorphology of the peat

- The peat characteristics

- The depth of peat

- Substrate strength and gradient

- The haul distance from quarries for imported fill.

- The potential for local re-use of excavated peat

- Construction and monitoring experience and expertise

Design of floating roads on peat

For many projects, the access roads will be a small component of the overall project cost. This is usually the case for wind farm projects. However, it is also true that design and construction of the access roads is critical to the efficient completion of the overall project as well as being a crucial component affecting the short and long-term environmental impact of these projects.

Good design practice for floating roads on peat will include the following stages.

- Complete a detailed ground survey, characterising the peat and local hydrology.

- Identify appropriate values for the peat strength.

- Finalise road layout. Checking with the end user or delivery contractor for limits on gradient, track width, turning radius and loading.

- Adjust the route to minimise environmental impact,

- Keep to flat ground as much as possible to minimise drainage works.

- When unable to avoid sloping ground, protect natural hydrological pathways. with culverts.

- Define construction and service life traffic loading for each road section.

- Design the floating road profile for each road section. Provide transitions between floating road sections and excavated sections.

- Schedule construction to allow for primary settlement without risk of failure.

- Monitor the work throughout construction, measuring and recording lateral movement and settlements. Be prepared to adjust the design based on observation and monitoring.

Design methods

Modern floating roads are usually designed with one or more layers of a geogrid to stabilise the aggregate fill. The geogrid interacts with the aggregate to form a mechanically stabilised layer that has a greater strength and stiffness compared to the aggregate alone. The result is that the overall thickness of the road structure can be considerably reduced - typically by up to 50%, while retaining the required bearing capacity and improving the load spreading capability of the road. The benefit of this is that the weight of the road is reduced, minimising settlement of the peat, while the strength and stiffness of the stabilised layer controls rutting at the road surface.

Geogrid selection for floating roads

It may be said that all geogrid types can stabilise aggregate, but not all geogrids are equally effective. The most efficient mechanically stabilised layer, enabling the thinnest and lightest road construction, will come from using the most effective stabilisation geogrid.

.jpg) Figure 6 - Floating roads stabilised with Tensar geogrid were used extensively for the construction of Glenchamber Windfarm, Scotland

Figure 6 - Floating roads stabilised with Tensar geogrid were used extensively for the construction of Glenchamber Windfarm, Scotland

A geogrid performs several functions in a floating road construction.

- Operational access – when the geogrid is laid directly over the peat bog, the geogrid provides a ‘snowshoe’ benefit, distributing load to allow access and movement over the peat. For the geogrid to be effective it requires a degree of flexural stiffness, a close rib spacing, strong ribs and strong junctions connecting ribs. Operatives can move safely about the site to install monitoring equipment and set out the alignment.

- Separation – As the first layer of aggregate fill is placed, the geogrid can prevent individual stones from punching down into the peat. If the upper layer of fibrous peat is intact, the combined geogrid and fibrous material will also prevent upward movement of fines into the aggregate layer. Where the fibrous layer may be thin or absent due to erosion or removal, a geotextile filter can be incorporated, usually bonded to the geogrid in the form of a geocomposite to aid installation.

- Stabilisation – The lower aggregate particles interlock with the geogrid and are confined within the apertures. Aggregate particles immediately above are also restrained by interlock with the confined aggregate particles. In this way a mechanically stabilised layer is built up. Additional layers of geogrid may be added at a defined vertical spacing to limit the distance between geogrids and maintain the stabilisation effect. The initial layer of stabilised material enables effective compaction of the upper layers to take place without distortion or punching- in of the stone.

The mechanically stabilised layer is significantly stiffer and stronger than non-stabilised aggregate. This enables the thickness of the road to be reduced without loss of bearing capacity and rutting resistance and with the all-important minimisation of the overall weight of the road to limit settlement.

The design thickness of the mechanically stabilised road is directly related to the efficiency of the geogrid in interlocking with and confining the aggregate particles – the stabilisation effect. It is known that this stabilisation effect is influenced by multiple characteristics of the geogrid, including polymer type, geometry, rib stiffness, rib aspect ratio, junction strength, and others. Tensar has continually introduced improvements to geogrid design and manufacture to enhance the stabilisation effect. Tensar’s latest geogrid, uses a complex geometry that provides in-plane and flexural stiffness, multiple aperture shape and size for maximum compatibility with graded aggregate, and utilises the co-extrusion of a black core and white interactive layers to enable enhanced particle interlock. Tensar InterAx, is the most efficient and effective stabilisation geogrid ever produced by Tensar.

Construction of floating roads on peat

The construction methodology adopted must always take account of local site conditions and constraints, weather conditions, construction equipment and expertise. The following general guidelines are based on most typical conditions.

- Preparing the site – After marking out the road alignment, the site will be cleared of large items such as trees, shrubs, and rocks. The peat surface and tree roots should be left in place. Damage to the peat surface must be avoided. Local depressions or shallow gullies should be filed with logs, brushwood or other lightweight fill.

- Geogrid installation - The geogrid is supplied in rolls. These can be unrolled directly over the peat. In areas where the peat surface has been damaged or eroded, a geocomposite product (combined geogrid and geotextile) should be used. Alternatively, a geotextile filter fabric can be laid down before the geogrid is unrolled. The direction of unrolling is not critical, provided the required overlap (recommended by the manufacturer) between adjacent rolls is adhered to. Construction plant should not travel directly over the geogrid.

- Fill placement – The initial layer of fill material will be an aggregate with particle size and grading specified to meet the geogrid manufacturers requirements for efficient interlock. The fill is ‘cascaded’ onto the geogrid to avoid shoving and movement of the geogrid. The first layer must be a minimum of 150mm. Successive layers are built up to the specified thickness. Typically, one or two layers of geogrid will be required but it could be more depending upon the loading and peat conditions. Vertical spacing between geogrid layers will be specified in the design.

- Compaction of the fill – The lower fill layers are usually tracked over to provide some compaction and improve interlock of aggregate particles into the geogrid apertures. Subsequent layers of fill should be compacted by non-vibratory roller. Heavy vehicles must be always kept away from the road edges. A safe running zone should be indicated and adhered to.

- Monitoring – The construction process should be closely monitored throughout. Measurements of lateral movement and settlement should be taken and reviewed by someone experience in construction over peat. The designer and contractor must be prepared to modify the design or construction methodology in response to the actual site condition.

Experience and knowledge of construction over peat is valuable when preparing and reviewing construction methodology. Tensar can advise designers and contractors on suitable methods appropriate to specific project conditions.

Looking to construct a floating road on peat? Tensar's Design Team can help

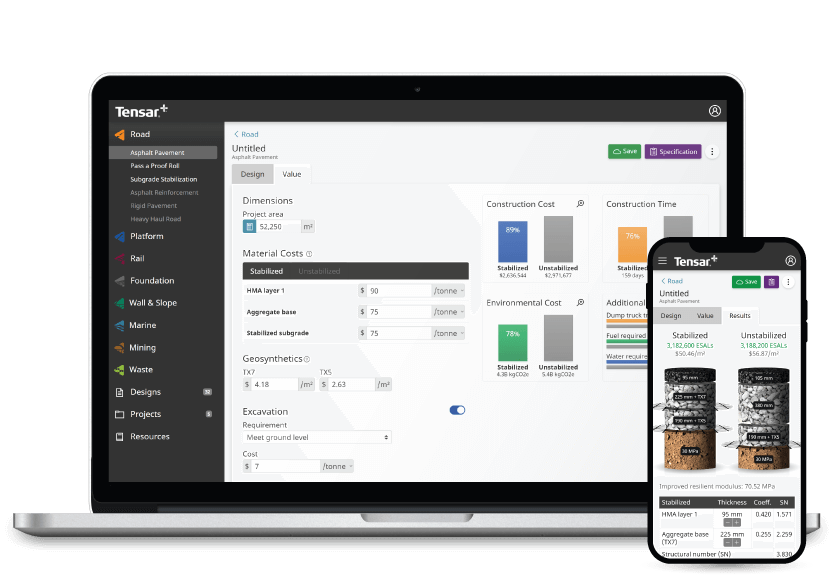

Working on weak or variable ground usually presents considerable construction challenges. But Tensar’s technology and expertise in subgrade stabilisation not only improves performance but is proven to reduce costs and the environmental impact of subgrade improvement too.

Tensar’s design team can produce a free of charge “Application Suggestion” to illustrate what Tensar can achieve and how much value can be added to your project.

Please submit you project details on the form via the button below and one of our dedicated design team will be in touch to support.